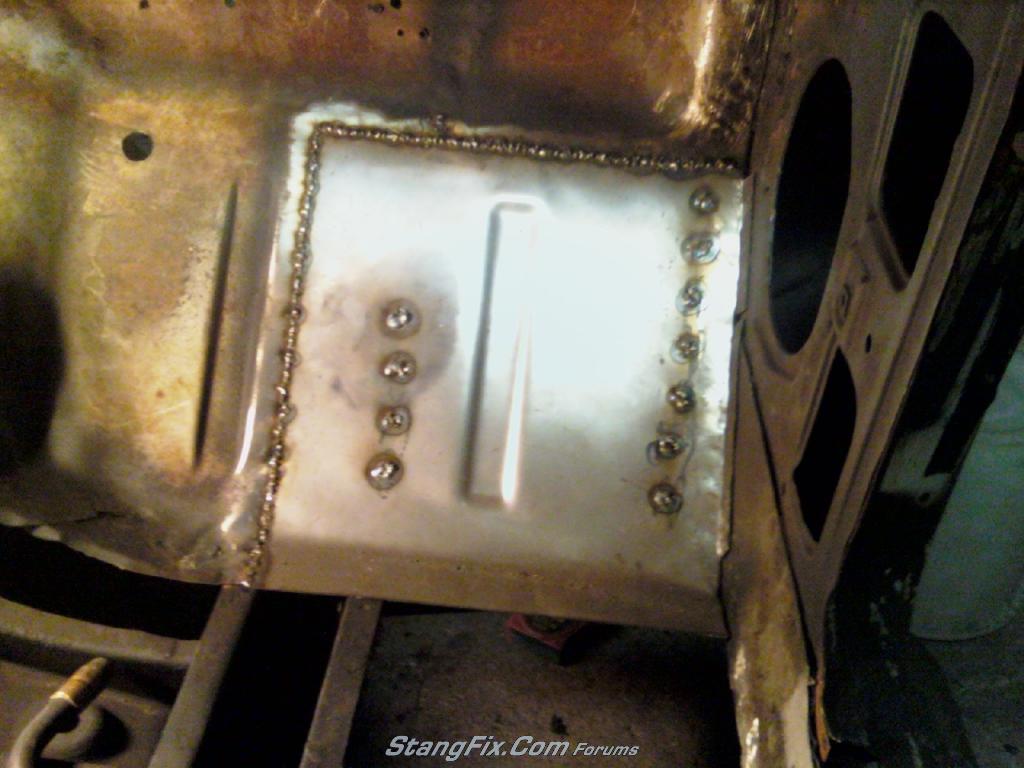

70_fastback came over and helped me on man floors this morning! Pan fits real good for a test fit "or at least I think it fits good". There are a few gaps along the rockers, but for just setting it in not bad. I will try to get some pics up. The floor pan is from Dynacore. Know is anyone up for doing a Extreme makeover Mustang Edition. I need to replace a frame rail,torque box,cowl, and shock towers. Also trunk.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Hello there guest and Welcome to The #1 Classic Mustang forum!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

One peice pan installed,70 mach 1

- Thread starter rusty1970

- Start date

manley

Member

Cool... are you just test fitting it, or did you weld it in? I have finished my torque boxes and toe boards and will be putting the floor in this week or next.

Badass70

Member

looks like it fits really well.. i replaced both left and right floor pans last year..

Drivers side frame rail is shot! Aslo that same side torque box is not there, anymore! We where going to put the floor pan extensions in but after looking at them they didnt fit right. Instead of the lip that welds to the rocker area being bent up it was down. A pain to weld from the underside and the torque box would be in the way. But, this is also beyond by scope of knowledge

70_Fastback

Hell Bent for Speed

Yeah, we need a BobV, SKip, Dan & Mark get to gether kind of day to knock that thing out. The entire upper and lower cowel needs to come out. As well as the fire wall...

But first Kyle needs to get the rust cleaned up and gone. That will take a while.

But first Kyle needs to get the rust cleaned up and gone. That will take a while.

manley

Member

"rusty1970" said:Drivers side frame rail is shot! Aslo that same side torque box is not there, anymore! We where going to put the floor pan extensions in but after looking at them they didnt fit right. Instead of the lip that welds to the rocker area being bent up it was down. A pain to weld from the underside and the torque box would be in the way. But, this is also beyond by scope of knowledge

There is a lot of extra metal on the floor extensions. I only cut out enough of my original extensions to get rid of the rust. I cut off the lip that goes against the rocker on both new extensions. Then I laid the new pieces over the place where they would be installed and started "roughing" them in, getting it close to the final shape.... when I got closer, the new extension starts fitting better and then you can tell where it will need to be formed better to mate against the original floor. When I got really close to having the shape I needed, I clamped the new extension down and then used some spray can primer to outline where I would need to make the final cut. Still, when making this cut, I was cautious and left a bit extra and slowly cut it down so that I could butt the new extension to the original metal.

Just take your time and don't take off too much metal at a time! I'm mostly happy with my results... my welding leaves a lot to be desired, but the extensions are in!

Last edited by a moderator:

70_Fastback

Hell Bent for Speed

See Kyle, I told you that outer lip goes up.

70_Fastback

Hell Bent for Speed

Don't listen to Skip, Kyle. He knows how to work the power tools.

Spent the day grinding! Fun,fun, and more fun!I have the inner rockers cleaned and all of the sorounding areads aswell. I alos canned the idea of the floor pan extensions in favor of extension/firewall combo. I also crawled under the car and did some more cleaning. Also checked out a few things under there as-well. Buy the time I am done with this car I will have all of Dynacores part numbers memorized.

70_Fastback

Hell Bent for Speed

And just think, you get to drill all of those parts to for cherry welds too. :thu

sigtauenus

Active Member

Get one of these for $40 and save a couple of hours drilling.

http://www.harborfreight.com/air-punch-flange-tool-1110.html

http://www.harborfreight.com/air-punch-flange-tool-1110.html

70_Fastback

Hell Bent for Speed

"sigtauenus" said:Get one of these for $40 and save a couple of hours drilling.

http://www.harborfreight.com/air-punch-flange-tool-1110.html

Thanks for that link Sam! I want one now too.