Being pneumatic and so inexpensive there is no speed control so it really goes. Ideally you'd want to be able to regulate the speed for various metals to get optimum cutting without overheating, etc. I have no doubt the cutting bit can eat stainless just not sure how bad it would bite back. I'll see if I have something laying about I can try it on and let you all know how it does.Slick piece of business Terry! Any feel for how it would handle stainless?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Hello there guest and Welcome to The #1 Classic Mustang forum!

To gain full access you must Register. Registration is free and it takes only a few moments to complete.

Already a member? Login here then!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cool New Tool Thread

- Thread starter Horseplay

- Start date

kb3

Well-Known Member

Not quite as cool as all of Terry's new tools, but I love adding things to my collection even if I won't be using them that often. I decided to take on the rebuild of the 4R70W transmission for my next project. One to save on cost, and two just to say I did it. By the time I buy the specialty tools and a high quality rebuild kit I will still be in for less than half of the local shop doing the work. Yes, I discount my labor hours to zero!

The guy I have purchase several rebuild kits from, http://www.badshoeproductions.com/index.html , sells some homemade tools to make the job easier. If you haven't seen his videos, he does a great step by step job of showing you how to rebuild a trans, diff, etc. So I purchased several of his 4R70W/AOD tools to make sure my rebuild is spot on. Spring compressors, bushing driver and a host of seal sizers to help make sure the seals go in without catching.

The guy I have purchase several rebuild kits from, http://www.badshoeproductions.com/index.html , sells some homemade tools to make the job easier. If you haven't seen his videos, he does a great step by step job of showing you how to rebuild a trans, diff, etc. So I purchased several of his 4R70W/AOD tools to make sure my rebuild is spot on. Spring compressors, bushing driver and a host of seal sizers to help make sure the seals go in without catching.

That is exactly why I made this thread, Ken, so people can post up stuff like your transmission tools and the source so we can all find new sources for specialty stuff. I was thinking hard about going auto in the truck but the final cost was nearing $4k. Now that I know about this stuff my mind is wandering back to that idea again. Damn you! I just finished up the 5 speed crossmember too.

You have the concentration and focus of a puppy [emoji38]

Mark

Mark

Life is easier when one is simple. You should know that.You have the concentration and focus of a puppy [emoji38]

Mark

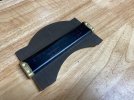

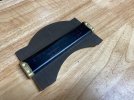

Here's a good one. A profile or contour gauge. This particular one uses pretty fine pins so it can capture very fine details. Simply press it against the surface of something and the pins shift to mimic the contour or profile. For around the house its great for transferring details to material for tasks such as cutting tile or flooring, for example. I got it for gauging how panel forming is coming into shape when doing metal work.

kb3

Well-Known Member

Here's a good one. A profile or contour gauge. This particular one uses pretty fine pins so it can capture very fine details. Simply press it against the surface of something and the pins shift to mimic the contour or profile. For around the house its great for transferring details to material for tasks such as cutting tile or flooring, for example. I got it for gauging how panel forming is coming into shape when doing metal work.

View attachment 34202

I’ve got that exact same one. Use it extensively for flooring and carpentry work around the house. Should work well for your use.

Today turned out to be a very good day. I've been on the hunt for a while now for something I think will be very useful in the garage. It seems I am constantly finding myself in situations when working on a project where if I only had one I could come to quick resolution to the problem task at hand. I really want a lathe.

Well, I got one. Missed out on one last night...again. Seems I'm always thisclose but there is someone who beats me to things every damn time. I was pretty disappointed as it was practically brand new and one of the better versions of the standard Chinese unit sold under a billion names. So early this morning as routine I fired up the computer and as I'm going through email and looking at stuff on my saved list on Marketplace a new ad pops up. It's close to me too. I message the guy and two hours later I'm in the car headed to go check it out. I was not disappointed.

Not only did I get the mini-lathe I was after, turned out the guy also had a benchtop mill he was looking to sell as well. Before long I was loaded down with both machines and a pirates bounty of accessories and tooling. Even better, the seller was an actual machinist and these units were something he picked up for at home doing simple little project stuff for his shooting hobby. He had already done some work on the machines to elevate their levels of operation and accuracy.

So I leave home to get a mini-lathe and come home with a full home hobbiest machine shop! Both machines, a ton of collets, mills, boring bar set-up, a couple different centers (one full roller), two tool posts and a bunch of bits, etc. assorted mix of various tooling and even a decent mill vise. Oh, and the mill is already set-up with a three axis DRO.

A couple pics.

h

h

Well, I got one. Missed out on one last night...again. Seems I'm always thisclose but there is someone who beats me to things every damn time. I was pretty disappointed as it was practically brand new and one of the better versions of the standard Chinese unit sold under a billion names. So early this morning as routine I fired up the computer and as I'm going through email and looking at stuff on my saved list on Marketplace a new ad pops up. It's close to me too. I message the guy and two hours later I'm in the car headed to go check it out. I was not disappointed.

Not only did I get the mini-lathe I was after, turned out the guy also had a benchtop mill he was looking to sell as well. Before long I was loaded down with both machines and a pirates bounty of accessories and tooling. Even better, the seller was an actual machinist and these units were something he picked up for at home doing simple little project stuff for his shooting hobby. He had already done some work on the machines to elevate their levels of operation and accuracy.

So I leave home to get a mini-lathe and come home with a full home hobbiest machine shop! Both machines, a ton of collets, mills, boring bar set-up, a couple different centers (one full roller), two tool posts and a bunch of bits, etc. assorted mix of various tooling and even a decent mill vise. Oh, and the mill is already set-up with a three axis DRO.

A couple pics.

h

hFU, Terry. I'm very jealous.

blu67

Well-Known Member

Here’s what I’ve recently got. Some of you may have seen one already but I like how this one works to compress the spring. Feels like a “safer” alternative to what’s normally out there.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I feel ya. Felt the same way for a long time until yesterday. I won't make it worse by telling you how much it all cost me.FU, Terry. I'm very jealous.

That's a good little tool, Chris. Not only safer but much easier to use.Here’s what I’ve recently got. Some of you may have seen one already but I like how this one works to compress the spring. Feels like a “safer” alternative to what’s normally out there.

One of the very few benefits of living where I do is the access to so many things. One of which is a Eastwood brick-n-motor store. While there is a lot of junk they market there are also some things I have come to like (i.e. their 2K aerosol spray paints) so it's nice to be able to hop in the car and go pick stuff up as needed. They had a "private VIP" sale the other day that I went to check out. At this point, I have pretty much assembled a poor man's hobby level metalworking shop and there were a couple missing components I wanted to see that they offered. The secondhand market searches were not turning up much.

Primarily, I was after a shrinker/stretcher set-up. I'd seen a few different foot operated stands people had made on Youtube and knew I'd need to go this route and had already sketched out my plans when I saw a video of one Eastwood was marketing. It is designed for their "Elite" head unit they sell for like $400. Not going there but the stand looked interesting. Pricing out the steel to build one myself plus the time involved made finding something possibly workable available retail made sense. Long story made just as long, I bought theirs. Got it on sale plus I had a coupon they had sent me to get the cost down to about $145 out the door. In all honesty, the steel alone would have run me just as much if I tried to copy it on my own.

After getting back home and putting it together I am VERY happy with the purchase. Very heavy, well constructed and a great design. I have to create a mount(s) for the shrinker and stretch head units I bought elsewhere to raise them a couple inches to get the geometry to match with the Eastwood Elite unit it was made for but that's just fine as it will allow me a way to make the mounting a clean, quick on/off design so I can swap between the two units as needed.

www.eastwood.com

www.eastwood.com

Primarily, I was after a shrinker/stretcher set-up. I'd seen a few different foot operated stands people had made on Youtube and knew I'd need to go this route and had already sketched out my plans when I saw a video of one Eastwood was marketing. It is designed for their "Elite" head unit they sell for like $400. Not going there but the stand looked interesting. Pricing out the steel to build one myself plus the time involved made finding something possibly workable available retail made sense. Long story made just as long, I bought theirs. Got it on sale plus I had a coupon they had sent me to get the cost down to about $145 out the door. In all honesty, the steel alone would have run me just as much if I tried to copy it on my own.

After getting back home and putting it together I am VERY happy with the purchase. Very heavy, well constructed and a great design. I have to create a mount(s) for the shrinker and stretch head units I bought elsewhere to raise them a couple inches to get the geometry to match with the Eastwood Elite unit it was made for but that's just fine as it will allow me a way to make the mounting a clean, quick on/off design so I can swap between the two units as needed.

Stand for 21489 Eastwood Elite Deep Jaw Shrinker Stretcher

Stand for 21489 Eastwood Elite Deep Jaw Shrinker Stretcher

Oh yeah, I found a set of the Chinese shrinker/stretcher units for a lot less than even HF ($120 vs $160). Exact same tools for 25% less. Ok, 20% if you use a coupon! Still a good deal and with free shipping.

Sheet Metal Fabrication Shrinker Stretcher Set Motorcycle #15301 | eBay

Hardened steel jaws have powerful force to curve and angle any mild steel to 18 gauge, aluminum to 16 gauge Great for auto body trim work, and door panel edging Units can produce tight angles, 3" radius Powder coated to prevent rust Pre-drilled holes in base for easy mounting Capacity 18 And 20...

www.ebay.com

kb3

Well-Known Member

It seems to me that you need two of those stands, otherwise you will be changing heads all the time.One of the very few benefits of living where I do is the access to so many things. One of which is a Eastwood brick-n-motor store. While there is a lot of junk they market there are also some things I have come to like (i.e. their 2K aerosol spray paints) so it's nice to be able to hop in the car and go pick stuff up as needed. They had a "private VIP" sale the other day that I went to check out. At this point, I have pretty much assembled a poor man's hobby level metalworking shop and there were a couple missing components I wanted to see that they offered. The secondhand market searches were not turning up much.

Primarily, I was after a shrinker/stretcher set-up. I'd seen a few different foot operated stands people had made on Youtube and knew I'd need to go this route and had already sketched out my plans when I saw a video of one Eastwood was marketing. It is designed for their "Elite" head unit they sell for like $400. Not going there but the stand looked interesting. Pricing out the steel to build one myself plus the time involved made finding something possibly workable available retail made sense. Long story made just as long, I bought theirs. Got it on sale plus I had a coupon they had sent me to get the cost down to about $145 out the door. In all honesty, the steel alone would have run me just as much if I tried to copy it on my own.

After getting back home and putting it together I am VERY happy with the purchase. Very heavy, well constructed and a great design. I have to create a mount(s) for the shrinker and stretch head units I bought elsewhere to raise them a couple inches to get the geometry to match with the Eastwood Elite unit it was made for but that's just fine as it will allow me a way to make the mounting a clean, quick on/off design so I can swap between the two units as needed.

Stand for 21489 Eastwood Elite Deep Jaw Shrinker Stretcher

Stand for 21489 Eastwood Elite Deep Jaw Shrinker Stretcherwww.eastwood.com

View attachment 34210

I should be able to build the pieces I have in mind to mount the heads to the stand this week. I'll post pics when done. What I have in mind will take just a minute or two to swap them. If used right I shouldn't need to swap out all that much. Most of the stuff I plan to make will require either or not some of both in terms of shrink/stretch. As long as you sneak up on it in use and don't over-shoot and have to reverse path no need to use both.It seems to me that you need two of those stands, otherwise you will be changing heads all the time.

My real issue is space anyway. If you take inventory of the new metal working tools I've added this summer you'll see even crammed together in the corner it takes up a lot of floor space.

1. Bandsaw

2. Bead Roller w/table

3. English Wheel

4. Planishing Hammer

5. Shrinker/Stretcher

6. Grinder and polishers on their floor stands

7. Press

8. Lathe (this will go on my older workbench soon)

9. Mill (This will likely get mounted to the top of a second 26" base cabinet like the one the lathe is sitting on in the pic earlier in the thread)

Then there are still the two welders on their respective carts. My tool boxes and workbenches. The air compressor. A couple flatheads, a 289 and a large parts rack. Plus the mustang and the truck and the riding mower all fighting for space in the 3 stall garage. Did I mention the wife thinks she should be able to park her car in the garage this winter? lol

Last edited:

funkaholik

Active Member

Check out this amazing tool - sadly, not mine. I was at a friend's place and she asked me to help with a project. I asked her for a tape measure, and she hands me this white plastic one that came with some made in China piece of assemble-it-yourself furniture she has. First thing I notice is that the inches are divided into 10, not 1/8s or 1/16ths. Next thing I notice is that these inches look awfully big. Here it is next to an actual tape measure. I told her that this must have been invented by a woman, definitely not a man, since 8 inches now reads as only 6.2, and 6 inches reads as only 4.6. Her waist, however, now measures 19 inches - she was very excited about that.

Attachments

GypsyR

just some guy

Finally popped for one of those cheapo plasma cutters. Stuff I've been putting off doing until I got one starting to stack up. I like it and it cuts stuff up a treat. Off eBay. It's not a "cut-50" but definitely related as the alleged instructions that came with it have Cut-50 printed on one of the pages. This one is pilot arc though. For some reason I had a pigtail of a 3/8" air hose and swapped the barbed fitting they provided for a matching 3/8" one. I think they expected me to use a 1/4" hose? Odd.

No plug on the power cord, which I understand isn't unusual. I thought to patch into an 110v extension cord I happened to have missing one end already but judge the wire gauge in it too small. I hear these things don't work all that well on 110 anyway. Borrowed the 220 plug off the lathe and used a spare length of Romex as an extension cord. Cuts as well as I could ask for. Cheap sucker. With shipping ended up being $135 all told. Not bad. Smells really weird though. I mean as soon as I opened the box.

That's an temporary E4OD adapter I slapped together out of some scrap for my floor jack to get the transmission out of my RV with. First trial was trimming some bits of that rustiness. I've a trailer project in progress and the drive gear stripped out on my band saw. This won't make as pretty cuts in angle but it sure does them faster.

No plug on the power cord, which I understand isn't unusual. I thought to patch into an 110v extension cord I happened to have missing one end already but judge the wire gauge in it too small. I hear these things don't work all that well on 110 anyway. Borrowed the 220 plug off the lathe and used a spare length of Romex as an extension cord. Cuts as well as I could ask for. Cheap sucker. With shipping ended up being $135 all told. Not bad. Smells really weird though. I mean as soon as I opened the box.

That's an temporary E4OD adapter I slapped together out of some scrap for my floor jack to get the transmission out of my RV with. First trial was trimming some bits of that rustiness. I've a trailer project in progress and the drive gear stripped out on my band saw. This won't make as pretty cuts in angle but it sure does them faster.

$135 for something with a pilot arc is insanely cheap! No wonder there was no plug. Is it a true pilot arc? What about consumables? A lot of the "Cut-50" versions use very specific stuff to get buyers to have to come back for them vs being able to buy the more generics on Amazon, etc.

I've been back and forth about getting one as I don't really see me needing one as much as simply wanting one. At that price it would pay for itself as compared to buying all the death wheels and saw blades pretty quick.

I've been back and forth about getting one as I don't really see me needing one as much as simply wanting one. At that price it would pay for itself as compared to buying all the death wheels and saw blades pretty quick.