apollard

Active Member

Well, I finally got some garage time (and limited my time in the politics board); actual progress made on the ’68. I’m about ready to send the 5.0 out for machining, and my goal is to have everything lined up to drop it in – cooling, exhaust, electrical, etc.

Improved how the Contour fan ($100 new) was attached to the rad, cleaned up the relays & wiring, ran two 25 amp circuits for these beasts. When they are on it sounds like a hurricane. Likely will need to switch to running one fan at a time, or run on the slow speed resistor (which came with the fan). It would cut on for only a minute of or so, and then off – and it is loud.

Fan installed

Close up of mounting. Made these before I learned to TIG weld, but they are not going anywhere. 1/8� alum angle bolted to the rad & the original mounts for the fan shroud. Marine grade rivets holding together, with the side of the shroud also sandwiched between alum for extra security.

The engine I’m using is a 5.0 from a ’97 Explorer, GT40P heads. I acquired it cheap ($75) before I knew of the issues with headers & the P heads. I considered scrapping the heads, then took it as a challenge. I’m sticking with Ford iron for a couple of reasons-

Cost – this is a driver, not an all out fun car. If I get 275-300 hp, that’s fine. More is just gravy. Alum heads are great, but this engine will be topping out around 5500 rpm anyway. I’d rather put that $ into paint & creature comforts for a driver. I have the tools to do the head work myself (except surfacing), so I’ll have <$200 in these after it’s done.

Challenge – my first cars were all factory iron. I like taking factory stuff and making it run. All I’ve read says that once you solve the header issue, the P heads will run great with a little massaging.

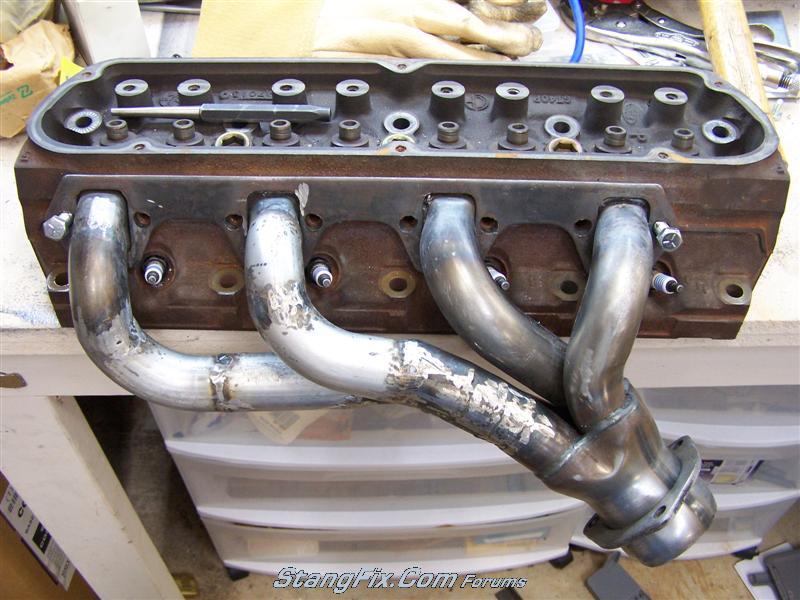

So, I picked up a set of Hedman shorties from Summit - $150 bucks, with ball sockets and header bolts. Great value, advertised as 18ga, but these measure out as 16ga steel. No starting pic, but here is the Hedman pic:

The issue with the P heads is the plug angle. Most headers come back sharply from the front drivers cylinders, which hits the plugs on a P head. You can see that on the left header in the pic above. The left side barely touched the front plug, but the second plug hit right in the middle of the tube. No way tighten them down w/o breaking the plug, much less get wires on them. Right bank needed no changes at all, perfect bolt up.

I don’t own a MIG or TIG. I’ve played with some friends TIGs before. I like the welds from TIG, so I decided to go that direction. I’m pretty good at making things, so I decided to ‘build’ a TIG to hook up to my AC/DC buzzbox.

http://www.az-zbum.com/welder.upgrade.shtml] [url]http://www.az-zbum.com/welder.upgrade.shtml[/url]

Right now, I’m just scratch starting, but I am gathering parts to build a HF start box, allowing me to weld aluminum. I’ll have under $250 bucks in the whole thing, and the satisfaction of knowing I made it myself.

I also picked up a couple of ½ inch U bends from Summit. Some thinking, thinking some more, and then I just decided to cut. Lots of sawing, fitting, filing, and welding later, I had the headers fitting, with at least 3/8� from the plug boots to the tubes. With heat shields, I’ve had good luck with that distance.

All welded in place. You can see the third plug is the tightest, but it should be fine.

The welds aren’t the best looking, but for my first TIG job, I’m happy. Full penetration of the 16 ga and only a couple of voids I had to fill – I ran 40 amps the whole time. I love how you can turn down TIG - I tried welding 20 ga butted with no problems & NO FILLER at 35 amps. I also found out that even though TIG doesn’t throw sparks and slag like stick or MIG, you still need to wear good welding clothes with long sleeves. It’ll give your forearms a wicked sunburn.

All cleaned up and ready for coating:

Anybody have any experience with the Rustoleum High Temp (2000F) paint?

Improved how the Contour fan ($100 new) was attached to the rad, cleaned up the relays & wiring, ran two 25 amp circuits for these beasts. When they are on it sounds like a hurricane. Likely will need to switch to running one fan at a time, or run on the slow speed resistor (which came with the fan). It would cut on for only a minute of or so, and then off – and it is loud.

Fan installed

Close up of mounting. Made these before I learned to TIG weld, but they are not going anywhere. 1/8� alum angle bolted to the rad & the original mounts for the fan shroud. Marine grade rivets holding together, with the side of the shroud also sandwiched between alum for extra security.

The engine I’m using is a 5.0 from a ’97 Explorer, GT40P heads. I acquired it cheap ($75) before I knew of the issues with headers & the P heads. I considered scrapping the heads, then took it as a challenge. I’m sticking with Ford iron for a couple of reasons-

Cost – this is a driver, not an all out fun car. If I get 275-300 hp, that’s fine. More is just gravy. Alum heads are great, but this engine will be topping out around 5500 rpm anyway. I’d rather put that $ into paint & creature comforts for a driver. I have the tools to do the head work myself (except surfacing), so I’ll have <$200 in these after it’s done.

Challenge – my first cars were all factory iron. I like taking factory stuff and making it run. All I’ve read says that once you solve the header issue, the P heads will run great with a little massaging.

So, I picked up a set of Hedman shorties from Summit - $150 bucks, with ball sockets and header bolts. Great value, advertised as 18ga, but these measure out as 16ga steel. No starting pic, but here is the Hedman pic:

The issue with the P heads is the plug angle. Most headers come back sharply from the front drivers cylinders, which hits the plugs on a P head. You can see that on the left header in the pic above. The left side barely touched the front plug, but the second plug hit right in the middle of the tube. No way tighten them down w/o breaking the plug, much less get wires on them. Right bank needed no changes at all, perfect bolt up.

I don’t own a MIG or TIG. I’ve played with some friends TIGs before. I like the welds from TIG, so I decided to go that direction. I’m pretty good at making things, so I decided to ‘build’ a TIG to hook up to my AC/DC buzzbox.

http://www.az-zbum.com/welder.upgrade.shtml] [url]http://www.az-zbum.com/welder.upgrade.shtml[/url]

Right now, I’m just scratch starting, but I am gathering parts to build a HF start box, allowing me to weld aluminum. I’ll have under $250 bucks in the whole thing, and the satisfaction of knowing I made it myself.

I also picked up a couple of ½ inch U bends from Summit. Some thinking, thinking some more, and then I just decided to cut. Lots of sawing, fitting, filing, and welding later, I had the headers fitting, with at least 3/8� from the plug boots to the tubes. With heat shields, I’ve had good luck with that distance.

All welded in place. You can see the third plug is the tightest, but it should be fine.

The welds aren’t the best looking, but for my first TIG job, I’m happy. Full penetration of the 16 ga and only a couple of voids I had to fill – I ran 40 amps the whole time. I love how you can turn down TIG - I tried welding 20 ga butted with no problems & NO FILLER at 35 amps. I also found out that even though TIG doesn’t throw sparks and slag like stick or MIG, you still need to wear good welding clothes with long sleeves. It’ll give your forearms a wicked sunburn.

All cleaned up and ready for coating:

Anybody have any experience with the Rustoleum High Temp (2000F) paint?

Last edited by a moderator: