I made a thread awhile back about two options for my design, the original Cobra Automotive style end brackets and what I felt was an improved version. I decided to run with my version, but in the end I doubt it will matter much. I would like to thank member hsr for getting the ball rolling on this and obtaining and drafting the dimensions up for the 65/66 crossmember, and would also like to thank jmn444 for measuring his CA crossmember and marking up the dimensions that are different on the 67-70 crossmember.

A little background on this. I installed a T56 trans in which I lowered the motor 1" and moved it to the rear 1.25". This meant the stock crossmember no longer fit. Rather than just making one similar to stock, I decided to tie in the LCA mounts to add more rigidity much like the Cobra Automotive crossmember does. I also wanted it to serve as a jacking point for now.

So since my situation was custom due to the oil pan location, I simply drew up the end brackets on a 2x8 piece of board, and cut out the center to follow the factory crossmember shape. I then put the board up in place like it was the crossmember, marked where cutting needed to occur, put the board back on the bench and cut as needed. I repeated this over and over until I had enough clearance. It resulted in the top of the crossmember center section being 1.25" lower than the stock piece.

The below drawings and dimensions are not intended for stock location engines. It will work for stock location engines, but it will just hang down lower. No guarantees of fitment for aftermarket oil pans. I'm working on drawings for this crossmember with a motor in its stock location, in case someone else wants to use this.

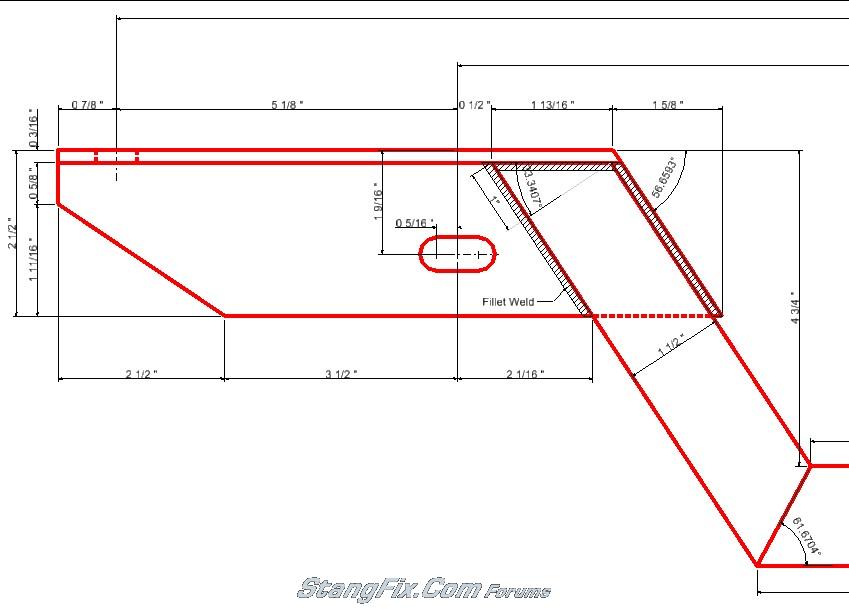

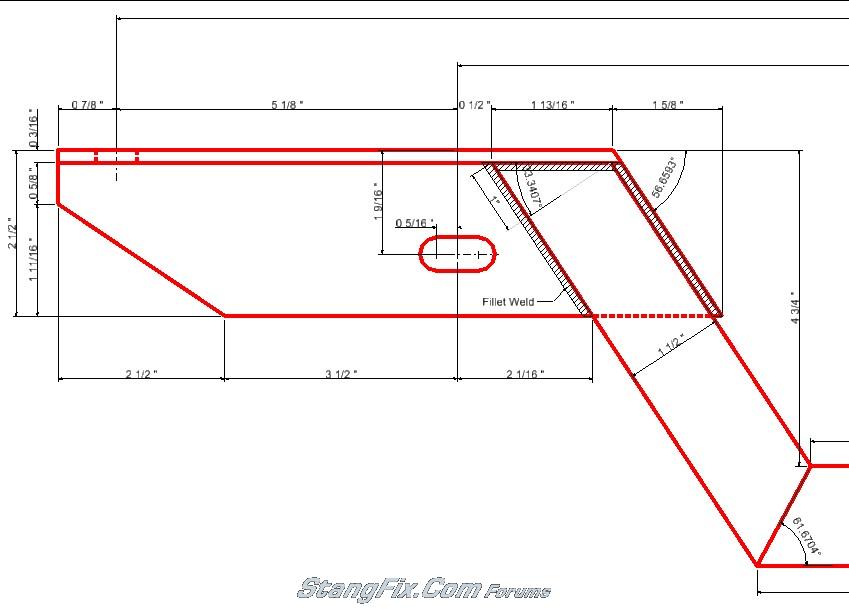

For the end brackets I used 2"x2.5"x3/16" angle. I believe the CA piece used 1.5"x2 5/16" bent plate. For the center sections, I used

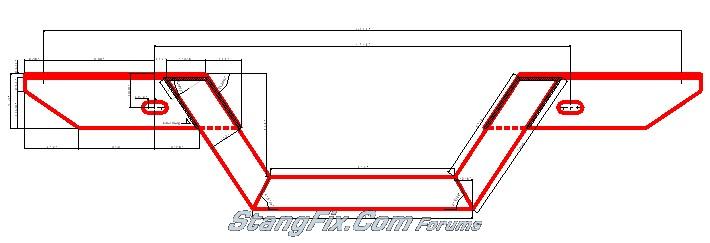

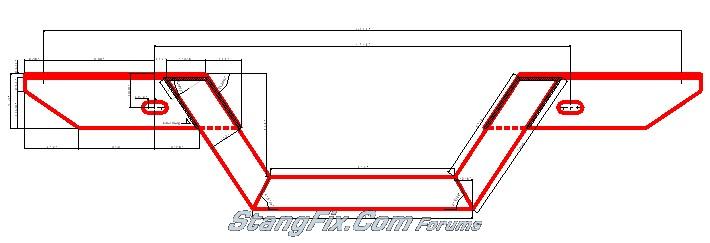

. Since the CA piece had 1.5" for the top leg of the end bracket with 3/16" thick, that meant if I used 1.5" square tubing with those CA dimensions the tube would stick out past the bent plate/angle 3/16", thus the reason to bump up to a 2" top leg. Now for some drawings and pics. I put some up close pics of the drawings as well as an overall view, as I'm not sure the dimensions will show too well in the overall view due to its length and picture size limitations.

. Since the CA piece had 1.5" for the top leg of the end bracket with 3/16" thick, that meant if I used 1.5" square tubing with those CA dimensions the tube would stick out past the bent plate/angle 3/16", thus the reason to bump up to a 2" top leg. Now for some drawings and pics. I put some up close pics of the drawings as well as an overall view, as I'm not sure the dimensions will show too well in the overall view due to its length and picture size limitations.

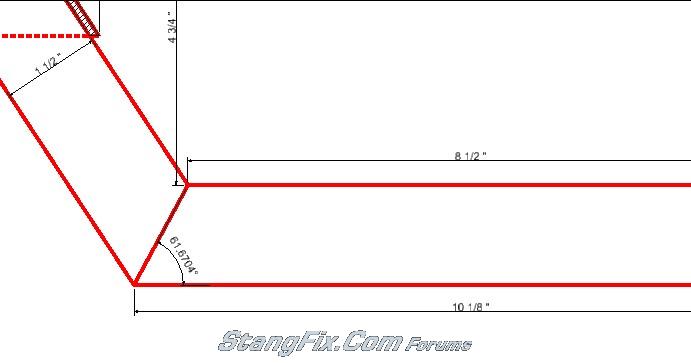

End Bracket:

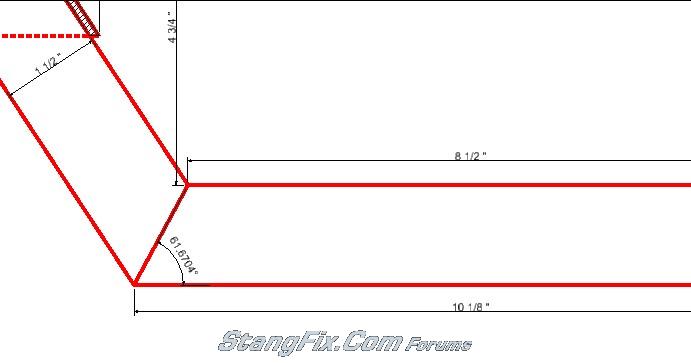

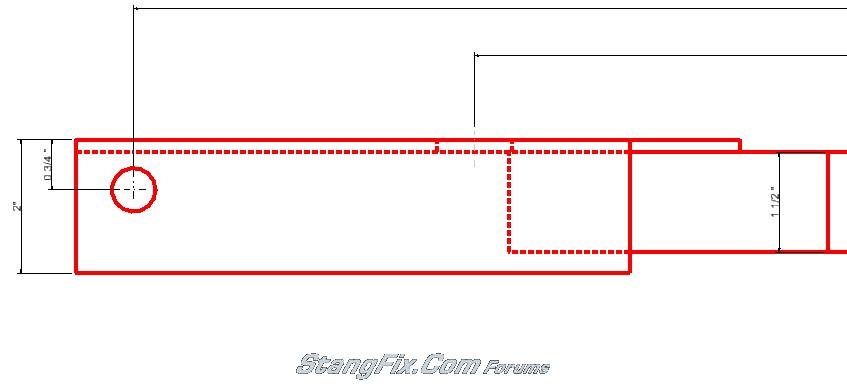

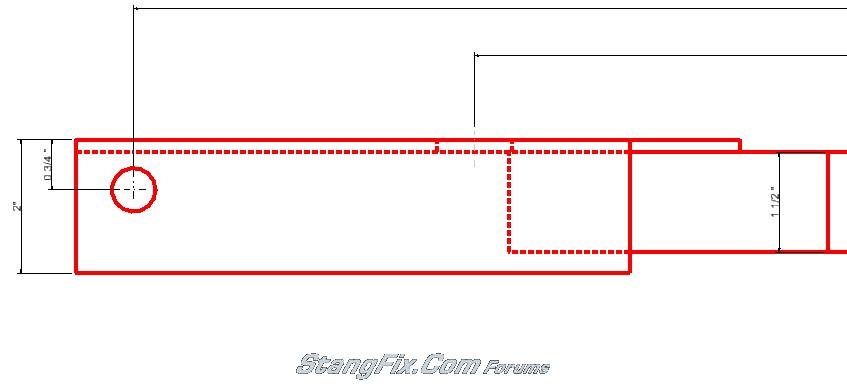

Bottom Tube section:

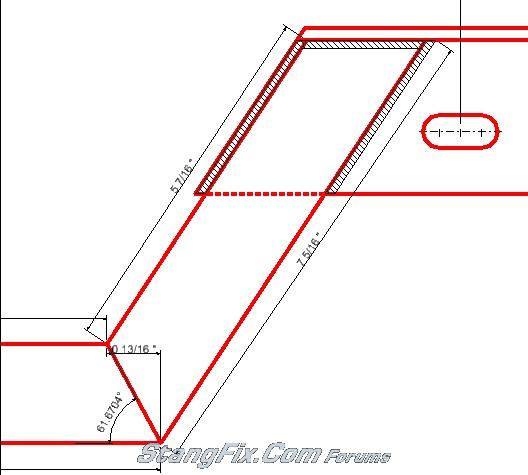

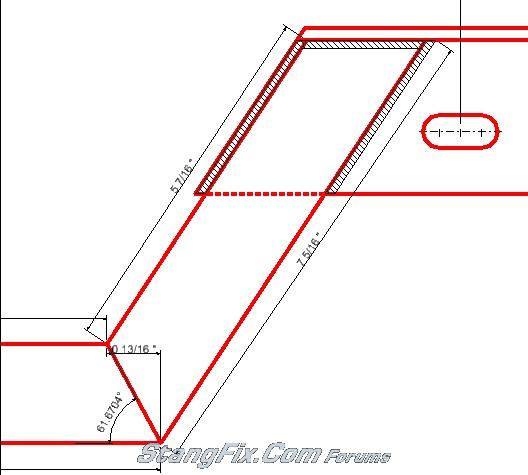

Angled Tube dimensions:

And top/plan view of end bracket:

And here is the finished product (still in painting process though):

Comparison to the stock piece:

And pics of it sat in place (but not fully installed). Pictures didn't turn out too well since I was on my back and the chrome oil pan created some nasty reflections/backlighting

As you can see, this car is no trailer queen by its dirt and grime. Its a driver It doesn't help the oil pan and PS pump is leaking, adding to the grime.

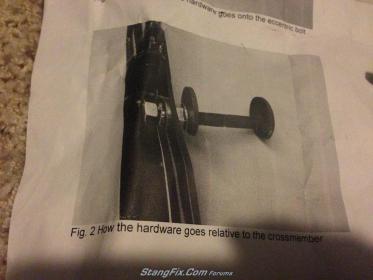

I have the Pro-Motorsports Eccentric Eliminators sitting on the workbench. My plan is to use a longer bolt with a nut in between this crossmember and the LCA, and another nut and washer on the face of this crossmember. For the pictures I just have the crossmember bolted in but not hooked to the LCA, as I have other suspension mods planned in the future and I don't want to mess with the alignment just yet (since its getting warmer out and I'll have the urge to drive the car).

I was a bit torn on how to handle the eccentrics. I had thought about removing the eccentric holder that is spot welded to the LCA mount and welding it to the face of this crossmember, which would make alignments MUCH easier. However, I was a bit concerned about the increase in bolt length and the distance between each eccentric plate. In the end I decided to leave it as is.

I also did not capture the top two dimensions of the overall view and the picture is tiny. The top dimension from frame bolt hole to frame bolt hole is 2'- 5 3/8". The dimension below it is from the centerline of LCA slotted hole to centerline of LCA slotted hole, and is 1'-7 1/8"

A little background on this. I installed a T56 trans in which I lowered the motor 1" and moved it to the rear 1.25". This meant the stock crossmember no longer fit. Rather than just making one similar to stock, I decided to tie in the LCA mounts to add more rigidity much like the Cobra Automotive crossmember does. I also wanted it to serve as a jacking point for now.

So since my situation was custom due to the oil pan location, I simply drew up the end brackets on a 2x8 piece of board, and cut out the center to follow the factory crossmember shape. I then put the board up in place like it was the crossmember, marked where cutting needed to occur, put the board back on the bench and cut as needed. I repeated this over and over until I had enough clearance. It resulted in the top of the crossmember center section being 1.25" lower than the stock piece.

The below drawings and dimensions are not intended for stock location engines. It will work for stock location engines, but it will just hang down lower. No guarantees of fitment for aftermarket oil pans. I'm working on drawings for this crossmember with a motor in its stock location, in case someone else wants to use this.

For the end brackets I used 2"x2.5"x3/16" angle. I believe the CA piece used 1.5"x2 5/16" bent plate. For the center sections, I used

End Bracket:

Bottom Tube section:

Angled Tube dimensions:

And top/plan view of end bracket:

And here is the finished product (still in painting process though):

Comparison to the stock piece:

And pics of it sat in place (but not fully installed). Pictures didn't turn out too well since I was on my back and the chrome oil pan created some nasty reflections/backlighting

As you can see, this car is no trailer queen by its dirt and grime. Its a driver It doesn't help the oil pan and PS pump is leaking, adding to the grime.

I have the Pro-Motorsports Eccentric Eliminators sitting on the workbench. My plan is to use a longer bolt with a nut in between this crossmember and the LCA, and another nut and washer on the face of this crossmember. For the pictures I just have the crossmember bolted in but not hooked to the LCA, as I have other suspension mods planned in the future and I don't want to mess with the alignment just yet (since its getting warmer out and I'll have the urge to drive the car).

I was a bit torn on how to handle the eccentrics. I had thought about removing the eccentric holder that is spot welded to the LCA mount and welding it to the face of this crossmember, which would make alignments MUCH easier. However, I was a bit concerned about the increase in bolt length and the distance between each eccentric plate. In the end I decided to leave it as is.

I also did not capture the top two dimensions of the overall view and the picture is tiny. The top dimension from frame bolt hole to frame bolt hole is 2'- 5 3/8". The dimension below it is from the centerline of LCA slotted hole to centerline of LCA slotted hole, and is 1'-7 1/8"

Last edited by a moderator: